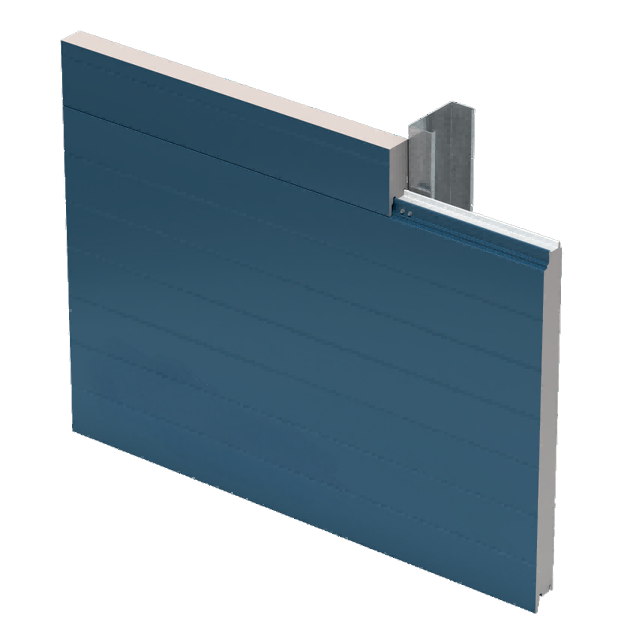

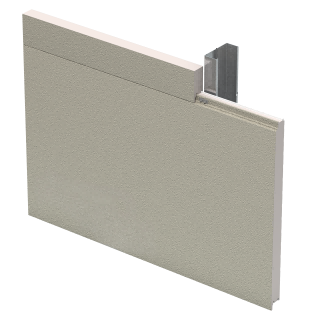

PIR/PU Sandwich Wall Panel

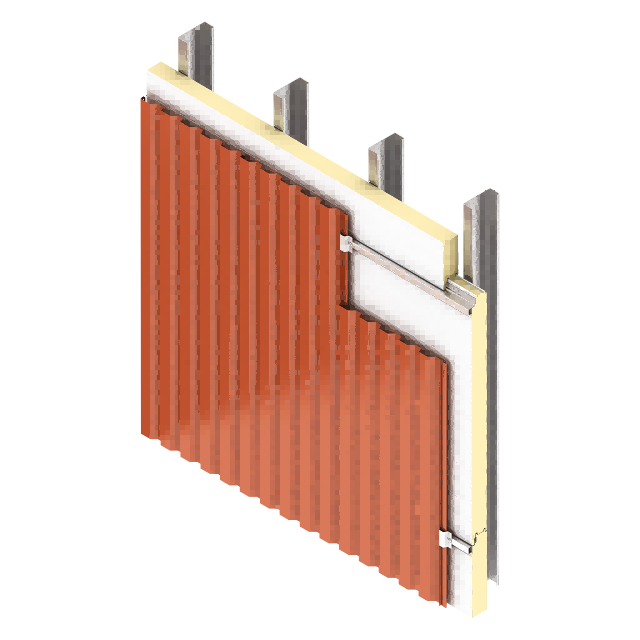

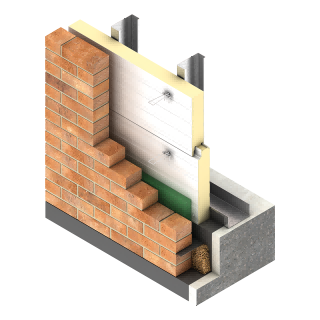

Polyurethane Insulated External Wall Panels boast excellent thermal insulation and fire resistance, with stable and reliable quality. Designed for efficient installation, they enhance airtightness and watertightness while delivering a sleek, modern aesthetic. Combining functionality and visual appeal, they are the ideal choice for high-performance building envelope systems.

Product Performance Advantages

Types Density kg/m3 Nominal Thermal

Conductivity λ[W/(m·K)]Thickness

mmThermal

Resistance R

m2

·k/WThermal

Conductivity

[W/(m2

·K)]PUR/PIR Sandwich Panel 38-43k 0.024 50 2.23 0.45 75 3.28 0.31 100 4.32 0.23 150 6.4 0.16 200 8.42 0.12 250 11.02 0.09

Q1:Extreme Energy Efficiency: Leading Thermal Insulation PerformanceQ1:

A: Ultra-low thermal conductivity significantly reduces building air conditioning and heating energy consumption, especially suitable for scenarios with high temperature control requirements such as cold storage and constant-temperature workshops.

High closed-cell content locks in temperature: The closed-cell structure minimizes heat loss from air convection, preventing long-term degradation of thermal insulation performance and ensuring sustained energy-saving effects

Q2: Safety & Reliability: Dual Excellence in Fire Resistance and Structural Stability

A: Classified fire resistance for diverse scenarios: PIR core material meets Class B1 (flame-retardant) standards, applicable to crowded places like stadiums and commercial buildings; PU core material is Class B2 (combustible), satisfying basic fire protection needs of industrial plants and warehouses.

Strong mechanical performance against risks: Wind pressure resistance ≥3.0 kPa, capable of withstanding severe weather such as typhoons and strong winds; lightweight properties reduce the load on the building main structure, lowering structural safety risks

Q3: Long-term Durability: Weather Resistance & Damage Resistance Reduce Maintenance Costs

A: Moisture-proof, anti-seepage, and anti-aging: Resists moisture and mildew in humid environments, avoiding panel bulging and corrosion caused by core material water absorption; the outer metal sheet coating is rust-proof, capable of withstanding sea breeze erosion even when used in coastal areas

Wide temperature range for multi-scenario adaptation: PIR core material can withstand -196℃~205℃, suitable for both low-temperature cold storage (below -40℃) and high-temperature environments; PU core material tolerates -185℃~110℃, meeting the temperature adaptability needs of most normal-temperature buildings and reducing panel deformation and cracking caused by temperature fluctuations.Performance Category

Performance Category Specific Parameter Index PIR (Polyisocyanurate) PU (Polyurethane)

Thermal Insulation Performance Thermal Conductivity (25℃) ≤0.0195 W/(m·K) ≤0.024 W/(m·K)

Thermal Resistance (100mm thickness) ≥5.13 (m²·K)/W ≥4.17 (m²·K)/W

Fire Safety Combustion Performance Grade Class B1 (Flame-Retardant) Class B2 (Combustible)

Oxygen Index ≥32% ≥26%

Smoke Density Rating (SDR) ≤75 ≤75