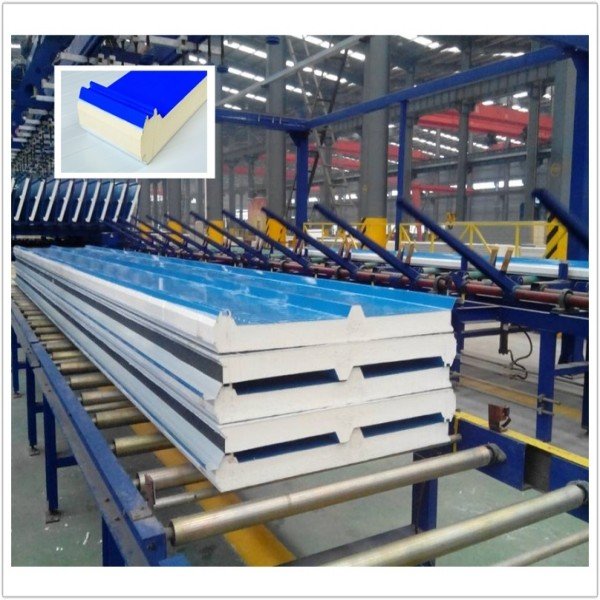

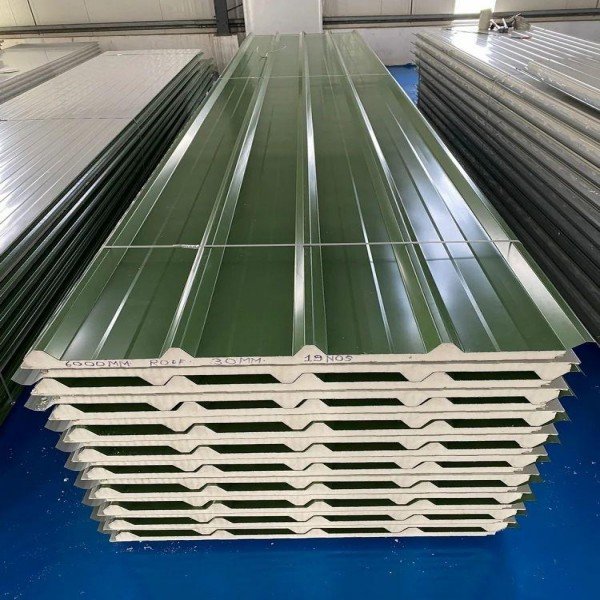

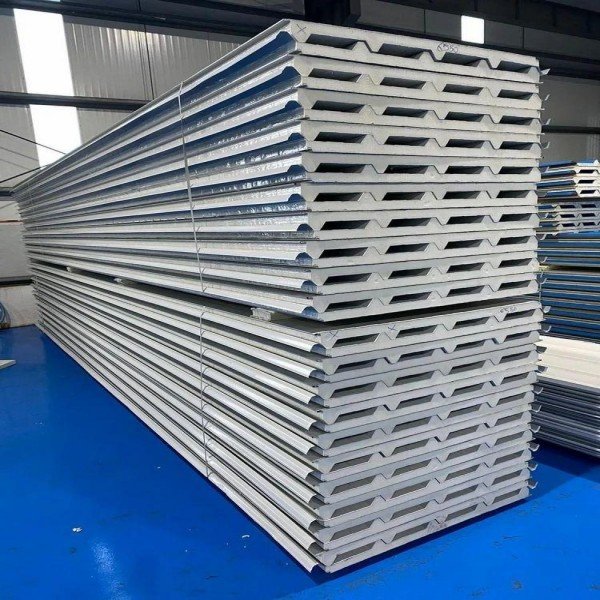

PIR/PU Sandwich Roof Panel

PIR/PU sandwich roof panels are high-performance enclosure materials specially designed for building roofs. With their excellent performance, they are widely used in various building scenarios, significantly reducing operation and maintenance costs. It is suitable not only for buildings with high requirements for insulation and waterproofing such as industrial plants, cold storage facilities and warehouses, but also for the roofs of densely populated places like exhibition centers and stadiums. In particular, it can meet the lightweight and high stability requirements of large-span roofs, making it the preferred material for modern building roof cladding.

Product Performance Advantages

Types Density kg/m3 Nominal Thermal

Conductivity λ[W/(m·K)]Thickness

mmThermal

Resistance R

m2

·k/WThermal

Conductivity

[W/(m2

·K)]PIR/PU Sandwich Roof Panel 38−43 0.024 50 2.23 0.45 75 3.28 0.31 100 4.32 0.23 150 6.4 0.16 200 8.42 0.12 250 11.02 0.09

Q1:High Efficiency & Energy Saving: Significantly Reduce Roof Temperature Control Costs

A: Ultra-Low Thermal Conductivity & Heat Retention

The thermal conductivity of PIR/PU core material enables over 50% higher energy efficiency compared to traditional rock wool roofs. It can effectively block solar radiant heat on the roof in summer and prevent indoor heat loss in winter, making it especially suitable for constant temperature requirements of large-span roofs such as factories and cold storage facilities.

High Closed-Cell Rate & Anti-Attenuation:

The closed-cell rate of PIR is ≥97% and that of PU is ≥95%. The closed-cell structure can prevent the core material from absorbing water and getting damp after rainwater seeps into the roof, fundamentally reducing the attenuation of thermal insulation performance and ensuring long-term energy-saving stability.

Q2: Superior Weather Resistance: Address Complex Environmental Risks of Roofs

A: Wind Uplift Resistance & Load-Bearing Capacity

The roof-specific panels have passed wind uplift tests and can withstand level-12 typhoons. They can bear loads such as roof maintenance personnel and snow, avoiding panel deformation and collapse.

Q3: Safety & Durability: Lower Long-Term Roof Operation and Maintenance Costs

A: Classified Fire Resistance for Adaptable Scenarios:

PIR core material meets the B1-class flame-retardant standard, with no molten drips during fires, suitable for people-intensive venues such as exhibition centers and commercial roofs. PU core material is B2-class flammable, meeting the basic fire protection needs of industrial factories and warehouses. Both have passed fire toxicity tests.

Wide Temperature Range Adaptability & Anti-Aging:

PIR core material can withstand temperatures from -196℃ to 205℃, and can be used stably in cold northern regions and high-temperature industrial factories, avoiding panel cracking caused by sudden temperature changes. The outer metal panel uses an aluminum-zinc coated base plate, with anti-corrosion life ≥25 years, reducing the frequency of roof renovation.