product

A cold room is a walk-in storage facility designed to maintain a consistent temperature, typically ranging from -25°C to +15°C, preserving the quality of products like fruits, vegetables, meat, seafood, dairy, and pharmaceuticals. It is widely used for food packaging, long-term storage, and blast freezing.

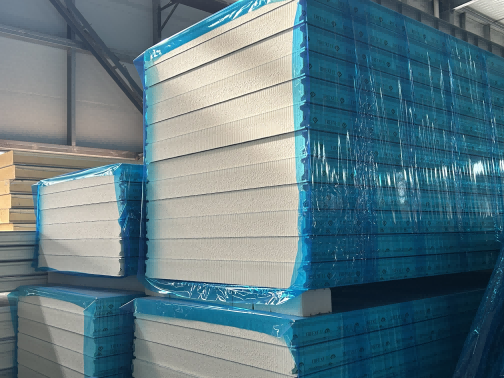

With 27 years of experience in manufacturing cold room panels and refrigeration equipment, and a decade of expertise in cold room engineering, Archi is a global industry leader. Our panels feature PUF (Polyurethane Foam) insulation with thermal conductivity as low as 0.022 W/m·K, ensuring superior energy efficiency. We use high-density stainless steel or galvanized steel for durability and corrosion resistance. Our refrigeration systems are equipped with intelligent controllers for precise temperature management and energy savings.

Archi has successfully completed projects worldwide, offering reliable and scalable cold room systems for industries of all sizes. Trust Archi to provide cutting-edge cold storage solutions that optimize efficiency and preserve product quality.

| Item | Specifications |

| Color | White (Optional) |

| Insulation Material | Polyurethane |

| Thickness of Cold Room Panel | 100mm,120mm,150mm, 200mm |

| Material of Panel Surface | Stainless Steel, Galvanized Steel |

| Thickness of Panel Surface Material | 0.426mm, 0.5mm |

| Cold Room Door | Hinged door, Swing door, Sliding door |

| Connection Type | Cam Lock panel or PIR Sandwich Panel |

| Compressor Brand | Bitzer, Copeland |

| Refrigerant | R22/R404A/R507 |

| Remark | ODM, OEM, Customized available |

Cold storage facilities are critical for preserving perishable goods by maintaining precise temperature and humidity levels, typically ranging from -30°C to +15°C, depending on the product. Industries such as agriculture, food processing, pharmaceuticals, and logistics rely on these facilities to ensure product quality, extend shelf life, and comply with safety regulations. For instance, fresh produce requires temperatures of 0°C to 4°C with 85-95% humidity, while frozen goods need -18°C or lower. Pharmaceutical companies depend on cold storage to safeguard vaccines and medications, often requiring ultra-low temperatures (-70°C) for certain biologics. Restaurants, supermarkets, and e-commerce platforms also utilize cold storage to meet consumer demand for fresh and frozen products. By investing in a cold storage facility with advanced insulation, energy-efficient refrigeration systems, and IoT-enabled monitoring, businesses can reduce spoilage, minimize waste, and optimize supply chain efficiency, making it a vital asset for industries handling temperature-sensitive goods.

Archi Company is a manufacturer of panels, cold storage doors, refrigeration equipment and evaporators

Cold Room Panel Install Material

Cold Storage Room Installation Part

Cold Room Celling Install

Use wire rope, mushroom head, flower basket ceiling

The top spacing is 5 meters and a lifting point

The support of steel structure is required

The height of five meters requires a suspended ceiling

Cold Storage Wall Install

Use L-shaped and U-shaped connection materials

Ground embedment according to insulation (100 or 150mm)

Use silicone and Pu foam to connect the panels

Use rivets and mushroom head screws to secure the panel

Archi Company Workshop Show

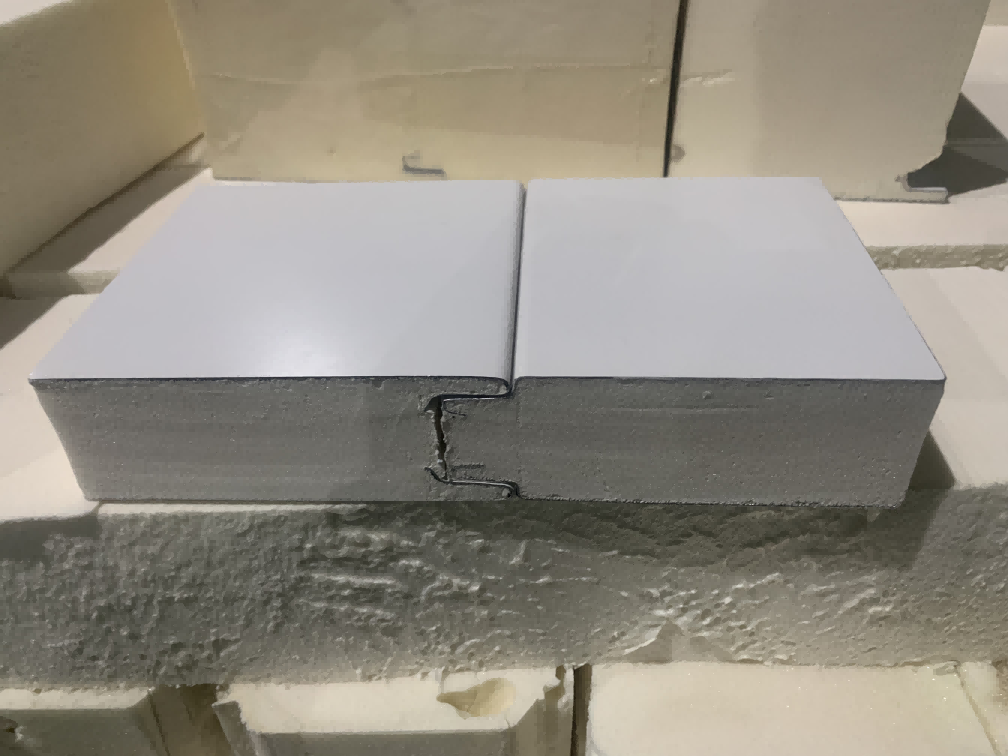

50/75;100-250 mm Different Connections Are Shown

Archi Company exports about 100,000 square meters of panels/400 set cold room door/1000 set compressor per year

Ecuador, Venezuela, Vietnam, Thailand, the United States, Canada, Saudi Arabia, etc

Ecuador flower banana storage cold storage

The use of 100mm cold storage panels is about 3000 square meters

With lifting door 2*2.5

Use stainless steel electric Swing cold storage door

Use the air curtain machine

Use DL-200 evaporator

Beijing food cold storage

The use of 120mm cold storage panels is about 1500 square meters

Use PLC electronic control system

Use manuel swing cold storage door

Use the air curtain machine

Use DL-200 evaporator

Vietnam bread seafood food factory project

The use of 50/120mm cold storage panels is about 8000 square meters

With lifting door 2.2*2.7

Use stainless steel electric Swing cold storage door

Use the air curtain machine

Use DD-160 evaporator

Thailand fruit cold storage

The use of 150mm cold storage panels is about 4000 square meters

With lifting door 2*2.5

Use stainless steel electric Swing cold storage door

Use the air curtain machine

Use DL-160 evaporator

Archi More Project

Please Click On The News For More Projects👈