In 2024, Archi was approached by an Australian customer through Alibaba who wanted to build a food and cold storage factory in Vietnam for the production of bread and frozen fish.

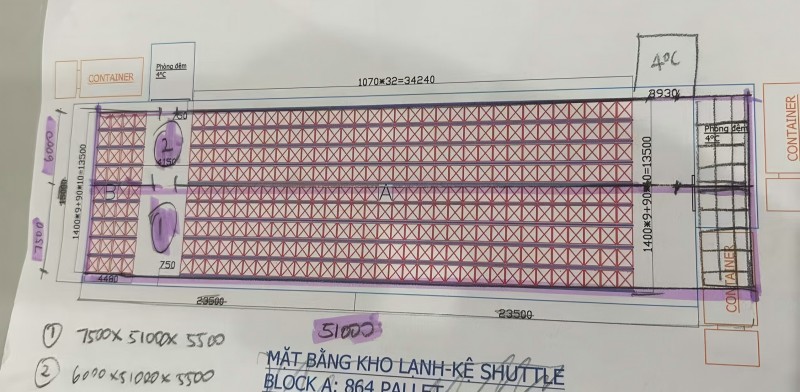

Project Drawing

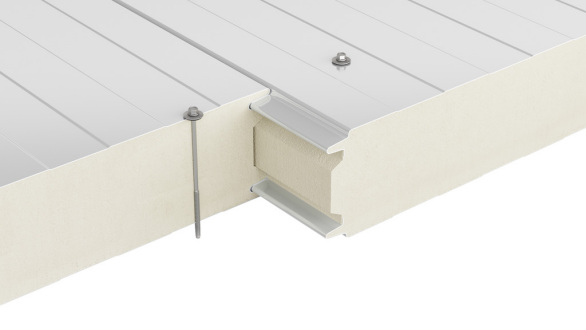

The customer used the form of investment factory construction in Vietnam, and purchased an old factory there for renovation. After visiting the project, the Archi team proposed the installation of auxiliary materials in conjunction with the installation of actual panels and equipment. Among them, the most considered by the customer is the steel structure plant built with color steel tile, whether there is enough weight to install the panel.

Pictures of the factory to be built

Over a period of three months, the Archi team and the client first decided to start with the procurement of the enclosure system, namely the panels and doors. The order quantity is approximately 7,000 SQM of 50mm pir sandwich wall panel (for food production) and 120mm panel (for cold storage). After paying the deposit for the order, customers also came to China to visit our factory.

Take photos with customers and load panels

At the same time, the Archi team provided the customer with the panel installation service, and the customer very much appreciated the Archi company's products and installation.

The Archi team went to Vietnam for construction

After that, Archi communicated with the customer about the refrigeration equipment. When customers visit our factory, they believe that we have the ability to manufacture excellent refrigeration equipment and evaporators, and we also have a service team of refrigeration engineers. Their last purchase is a screw parallel unit, compared to the traditional piston refrigeration unit, such screw compressors, will reduce energy consumption by 30%. It is also paired with evaporative cooling, with DD and DL series evaporators.

Installation materials for various refrigeration systems and evaporators and refrigeration equipment

After determining the refrigeration system, the customer was happy to pay for the order. The Archi team also completed the loading and delivery within a month's time frame.

Loading refrigeration equipment

After a week of shipping, the Archi team set out again to install the refrigeration system. After two weeks, the installation was successfully completed and was well received by customers.

All equipment is installed on site

Thanks again for the trust of the customer from Australia, this is a cold storage and food factory project close to 700,000 US dollars, we have a deep friendship with the customer, looking forward to our next cooperation.